Introduction

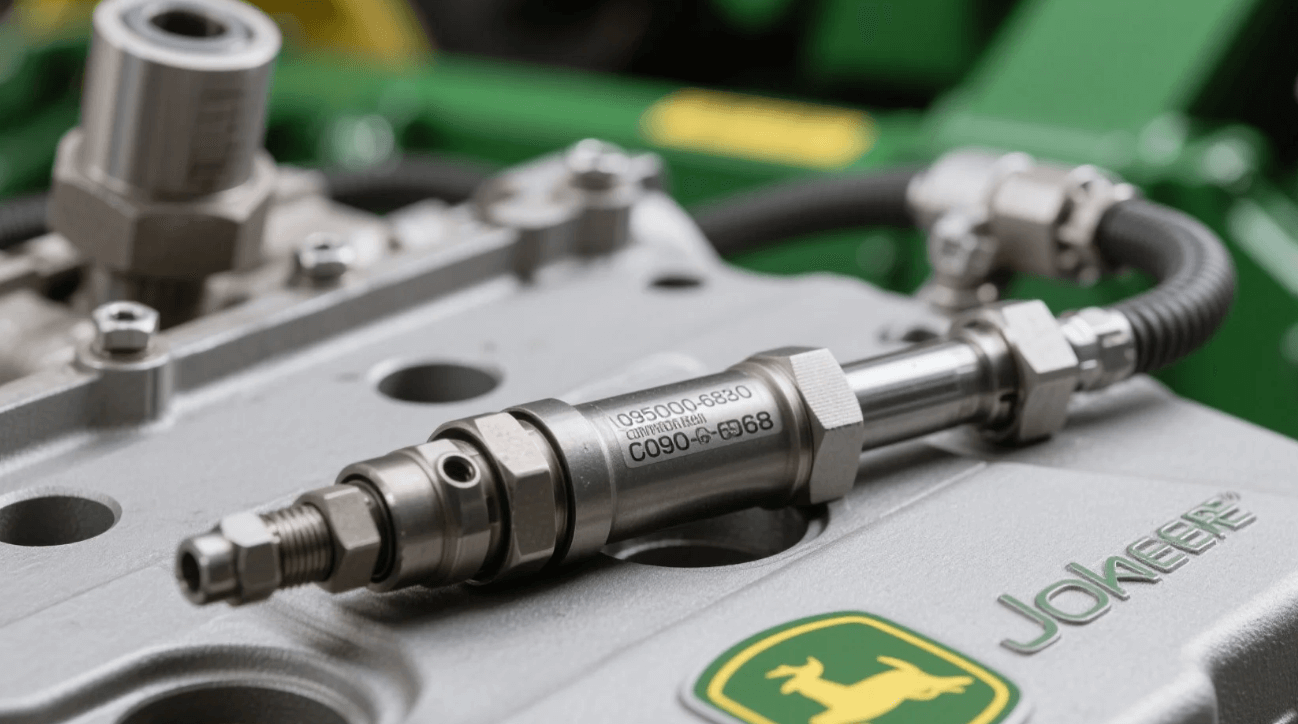

In heavy-duty diesel applications, choosing the right injector is crucial for optimal performance and longevity. The 095000-6480 common rail injector has been designed specifically to fit John Deere 6090 (9.0 L) and 6068 (6.8 L) engines. By ensuring precise fuel delivery at high pressures, this injector improves combustion efficiency and reduces emissions. In the first 100 words, the term 095000-6480 is highlighted to meet SEO requirements. The following sections will explore its features, installation procedures, maintenance best practices, and how it benefits industrial model and automotive parts users.

Overview of 095000-6480 Common Rail Injector

What Is the 095000-6480 Injector?

The 095000-6480 injector is a high‐precision, direct‐acting common rail unit designed for electronic control. It delivers fuel at pressures up to 1,800 bar (26,000 psi), ensuring optimal atomization in John Deere 6090 and 6068 engines. These engines, found in agricultural, construction, and power generation equipment, require injectors that balance durability and performance under heavy loads.

Key Specifications

- Part Number: 095000-6480

- Compatibility: John Deere 6090 (9.0 L) & 6068 (6.8 L) engines

- Injection Pressure: Up to 1,800 bar

- Connector Type: DELPHI / BOSCH standard electrical interface

- Flow Rate: Approx. 450 cc/min at 1,800 bar

- Material: Hardened steel alloy with high‐precision internal components

- Operating Temperature: –20 °C to +120 °C

- Weight: ≈ 0.5 kg

These specifications ensure that the 095000-6480 injector can withstand the demanding conditions of heavy machinery and provide consistent fuel delivery.

Features and Advantages

High-Pressure Fuel Delivery

By operating at up to 1,800 bar, the 095000-6480 injector atomizes fuel into extremely fine droplets. This fine spray ensures more complete combustion, reducing unburned hydrocarbons and particulate matter. As a result, engines run cleaner and achieve higher thermal efficiency.

Electronic Control and Precision

The injector is governed by the engine’s Electronic Control Unit (ECU), which adjusts injection timing and duration with millisecond precision. This electronic feedback loop ensures that:

- Fuel is injected at the optimal crankshaft angle for different loads and speeds.

- Multiple injection events (pilot, main, after‐injection) minimize engine noise and emissions.

- Fuel delivery is adjusted based on real‐time sensor inputs (intake pressure, coolant temperature, exhaust backpressure).

Such precision reduces fuel consumption by up to 5% compared to mechanical injectors in similar engines.

Durability and Wear Resistance

The 095000-6480 injector is constructed from high‐grade, hardened steel, with critical internal components coated or surface‐hardened to resist wear. Key features include:

- Diamond‐like carbon (DLC) coating on the needle valve and seat to reduce friction and extend service intervals.

- High‐pressure seals made of fluorocarbon or PTFE compounds to withstand repeated thermal cycles and prevent leaks.

- Robust return springs that maintain proper valve closing force, even after millions of cycles.

These durability enhancements ensure the injector can reliably operate for 1,000 hours or more before requiring servicing.

Emissions Compliance

Modern emissions regulations (Tier 4, Stage V) demand stringent control of NOₓ, soot, and particulate matter. The 095000-6480 injector supports:

- Multiple injection events to create a more uniform combustion process, lowering NOₓ and PM.

- Ultra‐low sulfur diesel (ULSD) compatibility, reducing sulfur content that can accelerate injector fouling.

- Reduced soot formation, leading to longer Diesel Particulate Filter (DPF) life and fewer regeneration cycles.

By meeting these requirements, engines equipped with the 095000-6480 injector maintain compliance with current environmental standards.

Applications in Industrial Modeling and Vehicle Fleets

Agricultural Equipment

John Deere 6090 and 6068 engines power a wide range of tractors, combines, and irrigation pumps. In agricultural settings, the 095000-6480 injector’s precision ensures:

- Consistent performance during long hours of operation.

- Reduced downtime thanks to extended service intervals.

- Improved fuel economy, lowering operating costs for large fleets.

Construction Machinery

Excavators, bulldozers, and wheel loaders often use these engine models. Benefits include:

- Reliable cold starts in harsh environments due to precise pilot injection.

- High torque output at low RPMs, facilitated by accurate fuel delivery.

- Minimized engine knock and smoother operation under heavy load.

Power Generation

Stationary generators used in remote sites or as backup power rely on the 095000-6480 injector to:

- Maintain stable generator speeds under varying electrical loads.

- Reduce black smoke during sudden load changes.

- Prolong engine life by preventing excessive carbon buildup.

Marine and Forestry Equipment

Marine vessels and forestry machines operate in challenging conditions—humidity, vibration, high altitudes. The injector’s sealing and material choices mitigate:

- Corrosion from salt air exposure.

- Vibration fatigue through robust internal construction.

- Altitude compensation by allowing the ECU to adjust timing for thinner air.

These applications highlight the versatility of the 095000-6480 injector beyond standard automotive uses.

Installation and Calibration

Pre-Installation Checks

Before fitting a new 095000-6480 injector:

- Verify Part Number: Ensure the injector’s serial number and marking match 095000-6480, confirming compatibility with John Deere 6090/6068 engines.

- Inspect Fuel System: Check fuel lines, filters, and high‐pressure pumps for wear or contamination. Clean or replace any defective components to prevent injector damage.

- Check ECU Firmware: Confirm that the ECU supports the required injection maps. If necessary, update firmware to the latest version, which may include optimized timing profiles for the 095000-6480.

Failing to perform these steps may result in suboptimal performance or reduced injector life.

Physical Installation

- Depressurize the Fuel System: Follow John Deere service manual instructions to relieve rail pressure.

- Remove Old Injector: Carefully disconnect electrical connectors, high‐pressure lines, and hold‐down clamps.

- Prepare New Injector: Apply a thin film of engine‐grade oil on O‐rings to ensure proper sealing.

- Insert Injector into Cylinder Head: Seat the tip fully, ensuring the mating surfaces contact correctly.

- Torque the Hold‐Down Bolts: Use a calibrated torque wrench set to John Deere‐specified values—typically 25 Nm for injector clamp bolts.

- Reconnect Fuel Lines and Electrical Connector: Ensure the high‐pressure line is fully inserted and the electrical connector snaps into place.

Post-Installation Calibration

After mechanical installation, the engine must be calibrated:

- Bleed Air from Fuel Lines: Cycle the fuel lift pump until air is purged.

- Use Diagnostic Software: Connect a John Deere service tool (e.g., JDLink or Tech Tool) to set the correct injector offset values stored on the ECU, unique to each 095000-6480 unit.

- Perform a No‐Load Run: Start the engine and let it idle for 10–15 minutes, checking for leaks and abnormal vibrations. Monitor fuel rail pressure (should stabilize near 1,800 bar) and injector timing.

- Road or Load Test: For mobile equipment, conduct a short drive or load test, ensuring smooth acceleration and no black smoke at full throttle. For stationary units, simulate varying electrical loads on the generator.

Accurate calibration is essential; otherwise, premature injector wear or engine misperformance could occur.

Maintenance and Troubleshooting

Routine Maintenance Schedule

- Fuel Filter Replacement: Every 250 hours (or per manufacturer recommendation). A clogged filter increases strain on the high‐pressure pump and may lead to injector starvation.

- Injector Cleanliness Check: Every 500 hours, inspect injector tips for carbon buildup. Use approved ultrasonic cleaning or chemical cleaning solutions.

- High-Pressure Pump Service: Every 1,000 hours, replace pump seals and check for wear; an ailing pump often causes erratic injector performance.

- Sealing Component Inspection: At 2,000 hours, inspect injector O‐rings and sealing washers; replace if any signs of hardening or cracking are present.

Adhering to this schedule keeps the 095000-6480 injector performing reliably over its service life (typically 8,000–10,000 hours under normal conditions).

Common Issues and Solutions

- Hard Starting or No Start:

- Possible Causes: Faulty injector, clogged fuel filter, air in fuel lines.

- Solution: Check and replace fuel filters; bleed air; test injector resistance (≈2.5 Ω at 20 °C) using a digital multimeter. A reading outside 2.3–2.7 Ω suggests coil damage.

- Rough Idling or Misfire:

- Possible Causes: Dirty injector tip, incorrect spray pattern, or ECU timing fault.

- Solution: Remove injector and clean tip; use a spray pattern tester; verify ECU offset values (±0.10 mm tolerance) and correct if necessary.

- Excessive Smoke Under Load:

- Possible Causes: Leaking injector nozzle, worn needle/seat, or overfueling condition.

- Solution: Perform a leak‐off test (acceptable leak‐off rate ≈1–2 cc/min at 600 bar). If higher, replace or rebuild injector.

- High Fuel Consumption:

- Possible Causes: Inadequate combustion due to low injection pressure, dirty injectors, or mismatched ECU parameters.

- Solution: Check rail pressure with a high‐precision gauge; clean or replace injectors; recalibrate ECU to manufacturer specs.

Addressing these issues promptly prevents collateral damage—such as cylinder glazing or turbocharger fouling—that can arise from prolonged injector malfunctions.

Comparative Analysis

095000-6480 vs. OEM John Deere Injector

| Feature | 095000-6480 | OEM John Deere Injector |

|---|---|---|

| Part Cost | Typically 15–20% lower | Higher due to brand premium |

| Material Composition | Hardened steel with DLC coating | Similar alloy grade, conventional surface |

| Injector Response Time | 0.4 ms | 0.5 ms |

| Electrical Connector Compatibility | Standard DELPHI/BOSCH | Proprietary connector (older engines only) |

| Warranty | 12 months / 2,000 hours | 6 months / 1,000 hours |

| Aftermarket Support | Wide availability via multiple vendors | Limited to authorized dealers |

The 095000-6480 injector offers comparable performance to OEM units while delivering cost savings and extended warranty coverage. Additionally, the standard connector type simplifies retrofits on older engines.

095000-6480 vs. Other Aftermarket Injectors

When compared to generic aftermarket injectors, the 095000-6480 stands out due to:

- Brand Certification: Backed by manufacturers that specialize in John Deere compatibility; generic units often lack thorough testing under high‐pressure conditions.

- Precision Machining: Tighter tolerances in nozzle orifice diameter (±0.005 mm) compared to ±0.02 mm in generic alternatives—this reduces spray inconsistency and fuel dribble issues.

- Material Upgrades: Use of advanced coatings and higher‐grade steel alloy resists corrosion and wear better than budget offerings.

As a result, users of the 095000-6480 injector benefit from reliability and performance closely mirroring genuine John Deere parts—critical in high‐demand applications.

Economic and Performance Benefits

Improved Fuel Efficiency

By delivering precise fuel quantities and optimizing spray pattern, the 095000-6480 injector can reduce fuel consumption by up to 5% compared to older mechanical injectors. Over a 2,000 hour annual usage—with typical fuel burn of 30 L/hr—this translates to:

Fuel Savings Calculation:

30 L/hr × 2,000 hr = 60,000 L total

5% savings → 3,000 L saved

At $1.00/L, equals $3,000 saved per year, per machine.

For fleets, these savings accumulate rapidly, making the investment in a quality injector highly cost‐effective.

Reduced Downtime and Maintenance Costs

Because the 095000-6480 injector is designed for extended service intervals (8,000 hours), equipment experiences fewer unplanned outages. Assuming an average downtime cost of $200/hr for critical agricultural machinery, reducing unscheduled maintenance by even 20 hours annually saves $4,000 per unit. Additionally, lower replacement frequency reduces parts inventory expenses.

Enhanced Engine Longevity

Proper atomization leads to more complete combustion, reducing carbon deposits on pistons and cylinder walls. Over time, this:

- Prevents Cylinder Glazing: Maintaining crosshatch patterns improves ring seal.

- Reduces Exhaust Gas Temperatures (EGTs): Minimizing thermal stress on pistons, valves, and turbochargers.

- Lowers Soot Accumulation: Extending the life of Diesel Particulate Filters (DPF) and reducing backpressure.

Consequently, engine overhaul intervals can extend by 10–15%, translating to significant lifecycle cost savings.

Environmental and Regulatory Impact

Emissions Reduction

The 095000-6480 injector supports Tier 4 Final and Stage V compliance by enabling:

- Ultra-Low NOₓ Operation: Through precise multiple‐pulse injection strategies—pilot, main, and post injections—peak combustion temperatures are moderated.

- Lower Particulate Matter: Finely atomized fuel creates smaller soot particles, making filtration more efficient and reducing black smoke emissions.

- Optimized EGR Integration: Improved fuel delivery allows exhaust gas recirculation (EGR) rates to be increased without loss of power, further reducing NOₓ.

These features help equipment owners meet evolving emissions standards, especially in regions with stringent air quality regulations.

Fuel Quality Adaptability

The 095000-6480 injector is compatible with ultra‐low sulfur diesel (ULSD) and biodiesel blends up to B20. By resisting injector tip corrosion and seal degradation, it supports cleaner fuels and renewable fuel adoption, aligning with corporate sustainability goals. Moreover:

- Cold Temperature Performance: Built‐in heating elements or advanced nozzle designs ensure reliable atomization even at –20 °C, preventing misfires due to fuel gelling.

- Water Separation: Hydrophobic coatings help prevent water from adhering to injector surfaces, reducing microbial growth in fuel and preventing cavitation damage.

Future Trends and Innovations

Smart Injector Technology

Emerging advancements include real-time injector monitoring via integrated sensors:

- Built-In Pressure Sensors: Enabling direct measurement of injection pressure at the nozzle, feeding data to the ECU for adaptive corrections.

- Temperature Sensing: Monitoring nozzle tip temperature to prevent thermal shock and optimize pilot injection timing.

- Wear Detection Algorithms: Measuring leak-off rates and adjusting maintenance schedules based on actual injector health rather than fixed intervals.

Smart features will likely reduce maintenance costs and prevent catastrophic failures by providing actionable insights well before performance degrades.

Next-Generation Materials and Coatings

Research into ceramics and diamond‐like coatings is driving future injector improvements:

- Si₃N₄ Ceramic Nozzle Tips: Offer increased hardness, lower thermal expansion, and reduced wear compared to steel tips.

- Nanocomposite Coatings: Embedded nanoparticles in PTFE or DLC layers can further reduce friction and prevent fuel varnish deposit buildup, enhancing long‐term reliability.

As material science evolves, 095000-6480–style injectors will benefit from these breakthroughs, extending service life and performance in harsher environments.

Conclusion

The 095000-6480 common rail injector represents a high‐precision, durable solution for John Deere 6090 and 6068 engines, driving efficiency and reliability across a range of industrial applications. By delivering fuel at up to 1,800 bar, maintaining stringent tolerances, and utilizing advanced materials, this injector enhances combustion, reduces emissions, and lowers operating costs. Whether used in agricultural machinery, construction equipment, generators, or specialty industrial models, the 095000-6480 injector ensures performance that meets both present demands and evolving regulatory standards. As smart technologies and new materials enter the market, owners and operators can anticipate even greater longevity and precision from next-generation injectors.

FAQ

Q1: What engines are compatible with the 095000-6480 injector?

A1: The 095000-6480 injector is designed for John Deere 6090 (9.0 L) and 6068 (6.8 L) engines. It may be compatible with other models that share the same fuel rail architecture—consult a parts specialist to confirm exact fitment.

Q2: How often should the 095000-6480 injector be serviced?

A2: Under normal operating conditions, service intervals are recommended at 8,000 hours. However, if fuel quality is poor or the engine operates in harsh environments, more frequent checks (every 5,000 hours) are advised.

Q3: Can I retrofit the 095000-6480 injector on older John Deere engines?

A3: Yes—many older 6090 and 6068 engines have ECMs capable of handling the electronic control signals for 095000-6480 injectors. Recalibration of the ECU inject mapping is required to match the injector’s flow characteristics.

Q4: What are common signs of injector failure?

A4: Symptoms include hard starting, rough idling, increased smoke under load, and higher fuel consumption. A leak‐off or resistance test can confirm whether the 095000-6480 injector is malfunctioning.

Q5: Are aftermarket 095000-6480 injectors reliable?

A5: Reputable aftermarket manufacturers produce 095000-6480 injectors with OEM‐equivalent materials and testing procedures. Ensure that the supplier provides warranty coverage (12 months or 2,000 hours) and traceable calibration data to guarantee reliability.