For any auto parts business, a well-stocked inventory of in-demand products is the key to success. Understanding which components fail most often allows you to anticipate customer needs and ensure a steady flow of sales. While an engine is a complex system of hundreds of components, some engine parts are replaced far more frequently than others due to normal wear and tear or scheduled maintenance. This guide will delve into the most common wear-and-tear items and essential replacement engine parts that every parts distributor should have on their shelves. By focusing on these high-turnover items, you can optimize your stock, enhance customer satisfaction, and build a reputation as a reliable source for quality auto parts.

The Foundation of Maintenance: High-Demand Wear Items

Certain engine parts are designed to be replaced at regular intervals. They are considered consumables or wear items, and their replacement is a fundamental part of a vehicle’s maintenance schedule. These items are consistently in high demand, making them a cornerstone of any profitable auto parts inventory.

1. Spark Plugs

Spark plugs are critical components in gasoline engines. They ignite the air-fuel mixture in the combustion chamber, which is what powers the vehicle. Over time, the electrodes on spark plugs wear down, leading to misfires, poor fuel efficiency, and a loss of engine power. Given their central role in ignition and their relatively short lifespan, spark plugs are one of the most frequently purchased engine parts. It’s important to stock a variety of types, including copper, platinum, and iridium, to meet the needs of different vehicle manufacturers.

2. Ignition Coils

Working in conjunction with spark plugs, ignition coils transform the low voltage from the car’s battery into the high voltage required to create the spark. Like any electrical component, they can fail over time due to heat and vibration. A failing ignition coil can cause a misfire, a rough idle, or a complete lack of power. Because they are often replaced in sets and are prone to failure, they are a high-volume item that should be a priority in your inventory.

3. Timing Belts and Chains

The timing belt or timing chain is a crucial part that synchronizes the rotation of the crankshaft and the camshaft. A broken timing belt can lead to catastrophic engine damage. Therefore, it is a key maintenance item with a specified replacement interval, typically every 60,000 to 100,000 miles. Some modern engines use a timing chain, which is designed to last the life of the engine, but they can still stretch or fail, leading to significant repair needs. Both are essential to stock, as they are a non-negotiable replacement for many vehicle owners.

4. Water Pumps

The water pump circulates coolant through the engine to prevent it from overheating. It’s a mechanical component that contains seals and bearings that can wear out. A leaking or failing water pump can lead to overheating, which can cause severe engine damage. Since the water pump is often replaced at the same time as the timing belt (due to the extensive labor involved in accessing it), it is a commonly paired item that should be stocked together.

The Critical Supporting Cast: Components That Fail Under Stress

Beyond standard wear items, certain engine parts are subject to stress and are known for their susceptibility to failure. These are often reactive purchases for customers dealing with a breakdown or performance issue, making them another category of must-have stock.

5. Thermostats

A thermostat regulates the flow of coolant, ensuring the engine operates at its optimal temperature. A stuck-open thermostat can cause the engine to run too cool, decreasing fuel efficiency, while a stuck-closed one can lead to rapid overheating. They are a relatively inexpensive but vital component that fails with some regularity, making them a profitable and fast-moving item.

6. Mass Airflow (MAF) Sensors

The Mass Airflow Sensor measures the amount of air entering the engine, which the Engine Control Unit (ECU) uses to calculate the correct amount of fuel to inject. A dirty or faulty MAF sensor can lead to a rough idle, poor acceleration, and decreased fuel economy. Since they are often exposed to dirt and dust, they are a common point of failure and a frequently replaced electronic component.

7. Oxygen Sensors

Oxygen sensors (or O2 sensors) measure the oxygen content in the exhaust gases. This data is fed to the ECU to fine-tune the air-fuel ratio. A bad oxygen sensor can cause a “Check Engine” light to illuminate, lead to poor fuel economy, and increase emissions. Due to their location in the harsh exhaust environment, they are prone to failure and are a staple replacement part for modern vehicles.

8. Fuel Pumps

The fuel pump transfers fuel from the gas tank to the engine’s fuel injectors. These pumps are constantly working and can fail over time due to debris in the fuel or general wear. A failing fuel pump can cause a car to stall, have trouble starting, or perform poorly under acceleration. Given their importance, they are a high-value, high-demand component that every distributor should have on hand.

The Consumables: Filters and Gaskets

Rounding out the list of essential stock are the items that are regularly consumed or replaced as part of basic maintenance. These items are often sold in high volumes and are a steady source of revenue.

9. Oil and Air Filters

Oil filters and air filters are arguably the most fundamental replacement engine parts. Oil filters remove contaminants from the engine oil, while air filters clean the air entering the engine. Both are replaced at regular intervals—oil filters with every oil change and air filters every 12,000 to 15,000 miles. They are a constant need for all vehicle owners and a reliable source of consistent sales.

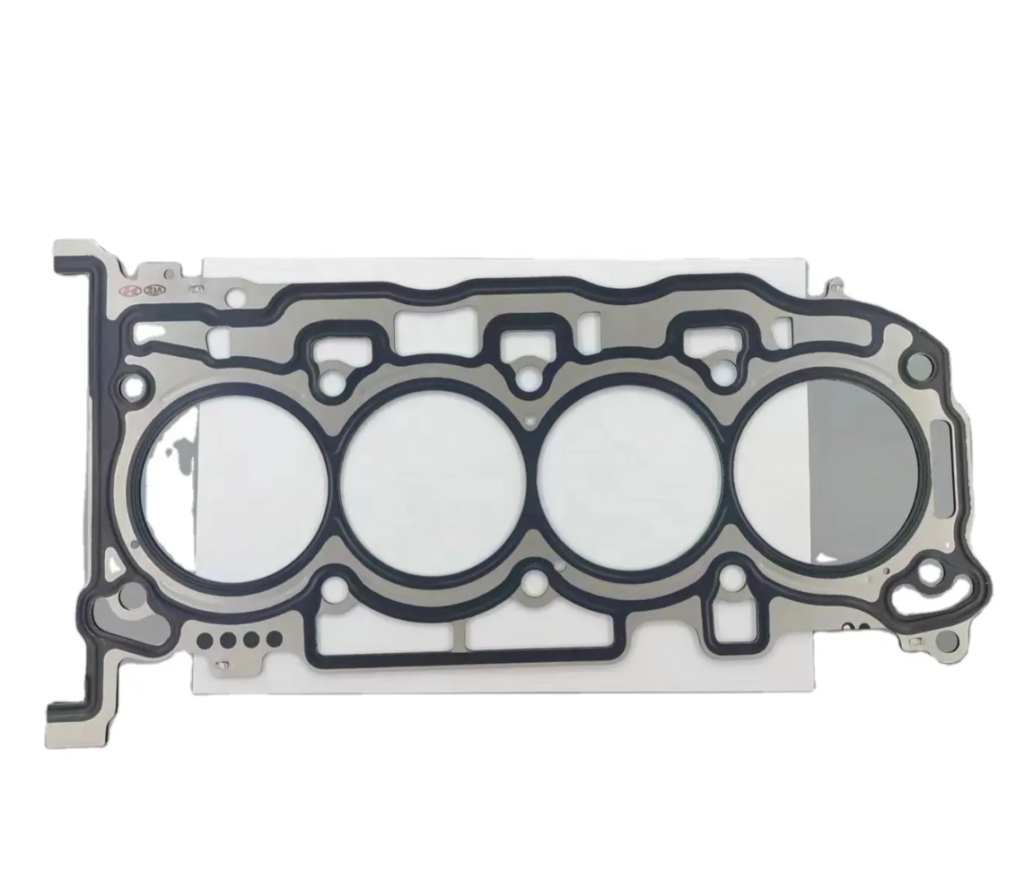

10. Gaskets and Seals

Gaskets and seals, such as valve cover gaskets and oil pan seals, are designed to prevent fluid leaks between two mating surfaces. Over time, they can dry out, crack, or become brittle from heat and pressure, leading to leaks. Since leaks are a common and serious issue, these items are frequently replaced during engine repairs and are a crucial part of any comprehensive inventory.

Conclusion

By understanding which engine parts are most frequently replaced due to maintenance schedules, wear, and failure, you can strategically stock your inventory to meet customer demand. From spark plugs and timing belts to sensors and gaskets, having these key components on hand ensures you are prepared to service a wide range of customer needs, from a simple oil change to a major engine repair. Focusing on these high-turnover items not only drives sales but also positions your business as a reliable and knowledgeable supplier in the competitive auto parts market.

FAQs About Engine Parts

Q1: How can I tell if a spark plug needs to be replaced? A: Common signs of a worn spark plug include engine misfires, a rough idle, poor fuel economy, and difficulty starting the car. A physical inspection will often show a worn or fouled electrode.

Q2: What’s the difference between a timing belt and a serpentine belt? A: A timing belt synchronizes the internal components of the engine (crankshaft and camshaft). A serpentine belt, on the other hand, drives the external accessories like the alternator, power steering pump, and air conditioner compressor.

Q3: Is it okay to use a cheaper, generic engine part? A: While generic parts may be cheaper, using original equipment manufacturer (OEM) or high-quality aftermarket parts is generally recommended. They are designed to meet specific standards and are often more durable, which can save you from future issues and costs.

Q4: How important is regular oil filter replacement? A: It is extremely important. The oil filter prevents dirt and debris from circulating through the engine, which can cause significant wear and tear on internal components. A clean oil filter is essential for the long-term health and efficiency of the engine.